News

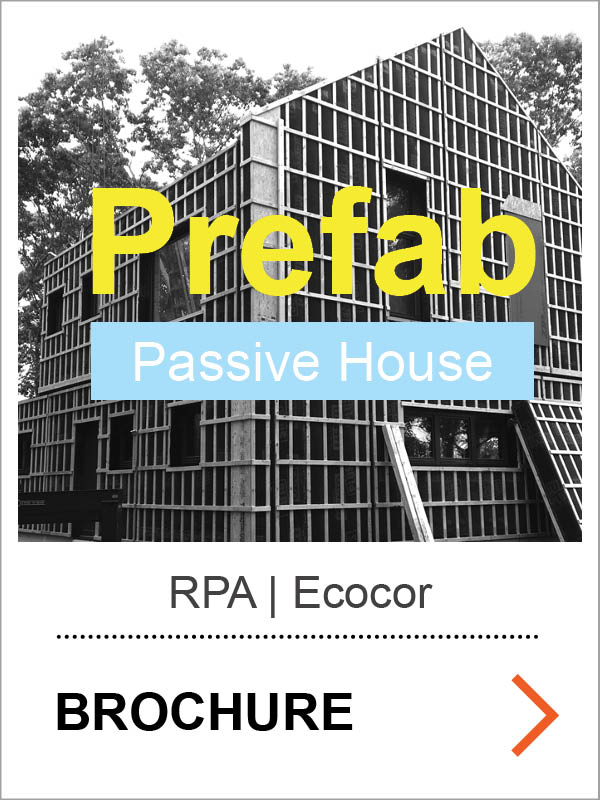

Ecocor Team Finishes Assembly of First-of-its-Kind Prefabricated Passive House Designed by Richard Pedranti Architect (RPA)

Prefab Passive House manufactured in advanced fabrication facility using state-of-the-art machines is assembled on site in less than one week.

Ecocor, a construction firm that manufactures, delivers and assembles Passive House buildings, has finished assembly of the Elizabeth Scott Prefabricated Passive House, which was designed by Richard Pedranti Architect (RPA), a full-service architecture firm focusing on sustainable and Passive House design. While Ecocor and RPA independently have extensive experience with site-built and prefabricated Passive Houses, Elizabeth’s house, which was panelized in Ecocor’s advanced fabrication facility, is the first in the United States to be manufactured using state-of-the-art machines imported from Sweden.

Ecocor, a construction firm that manufactures, delivers and assembles Passive House buildings, has finished assembly of the Elizabeth Scott Prefabricated Passive House, which was designed by Richard Pedranti Architect (RPA), a full-service architecture firm focusing on sustainable and Passive House design. While Ecocor and RPA independently have extensive experience with site-built and prefabricated Passive Houses, Elizabeth’s house, which was panelized in Ecocor’s advanced fabrication facility, is the first in the United States to be manufactured using state-of-the-art machines imported from Sweden.

Elizabeth worked with RPA to customize her own version of the Goldenrod Model Home from the Solsken Line of Prefabricated Passive Houses.

Once designed, RPA’s computerized building models automatically provided instructions to the Randek AB saw and production line inside the Ecocor facility, where the panelized wall and roof components are created.

Ecocor uses the highest quality building materials to manufacture their patent pending wall and roof components that are certified by the Passive House Institute (PHI) in Darmstadt, Germany. After the wall and roof components are fabricated using Ecocor’s state-of-the-art production line, they are loaded onto trucks and ready to be delivered onsite. Upon delivery, Ecocor’s team uses a crane to “fly-in” the wall and roof components before additional team members assemble the panels together.

“Manufacturing the wall and roof components in the Ecocor facility allows us to be extremely efficient when assembling the Passive House onsite,” said Chris Corson, Founder and Technical Director of Ecocor. “By using such advanced equipment and not having to worry about nuisances like the weather, we’re able to construct the highest-quality prefabricated homes much faster than typical site-built construction.”

Elizabeth’s Prefabricated Passive House is located on a lot adjacent to her parents’ “Post and Beam Passive Solar House” that was built in 1979 by legendary low-energy builder Bruce Brownell. After Ecocor assembles the wall and roof components, local builder partners will take over for interior fit and finish.“Manufacturing the wall and roof components in the Ecocor facility allows us to be extremely efficient when assembling the Passive House onsite,” said Chris Corson, Founder and Technical Director of Ecocor. “

“Prefabricated Passive Houses solves for the many deficiencies in modern home construction and represents the future of American home building,” said Richard Pedranti, Founder and Principal at RPA. “By combining the Passive approach to building design and prefabrication of the building components, Chris and I are able to efficiently deliver the healthiest, most comfortable homes on the market today.”

Passive House is the most stringent, low energy building standard in the world. Common in many European countries, Passive House takes advantage of super-insulated walls, internal heat gains and the sun coming through well-situated windows to produce the highest level of interior comfort available in a building today. Regardless of the weather outside, this 21st Century approach to home building reduces energy consumption by 80 to 90 percent compared to a conventional home, maintains a comfortable 68 to 72 degrees indoors all year-round and improves indoor air quality with a continuous supply of filtered fresh air.

See this article on http://www.prweb.com/releases/2017/03/prweb14142688.htm.

VIEW PROJECT PAGE