News

North America’s First Fully Prefabricated Passive Houses Could Revolutionize the Housing Market

A brilliant new partnership announced today could revolutionize the way Americans build their homes.

Ecocor has teamed up with sustainability-minded design firm Richard Pedranti Architect (RPA) to design and build North America’s most energy-efficient prefab Passive Houses starting with eleven model home designs. The factory-built homes not only give Americans the opportunity to buy a super insulated, energy-efficient home at what we presume will be an affordable price, but will also allow them to modify and customize their eco-friendly home to their tastes with ease.

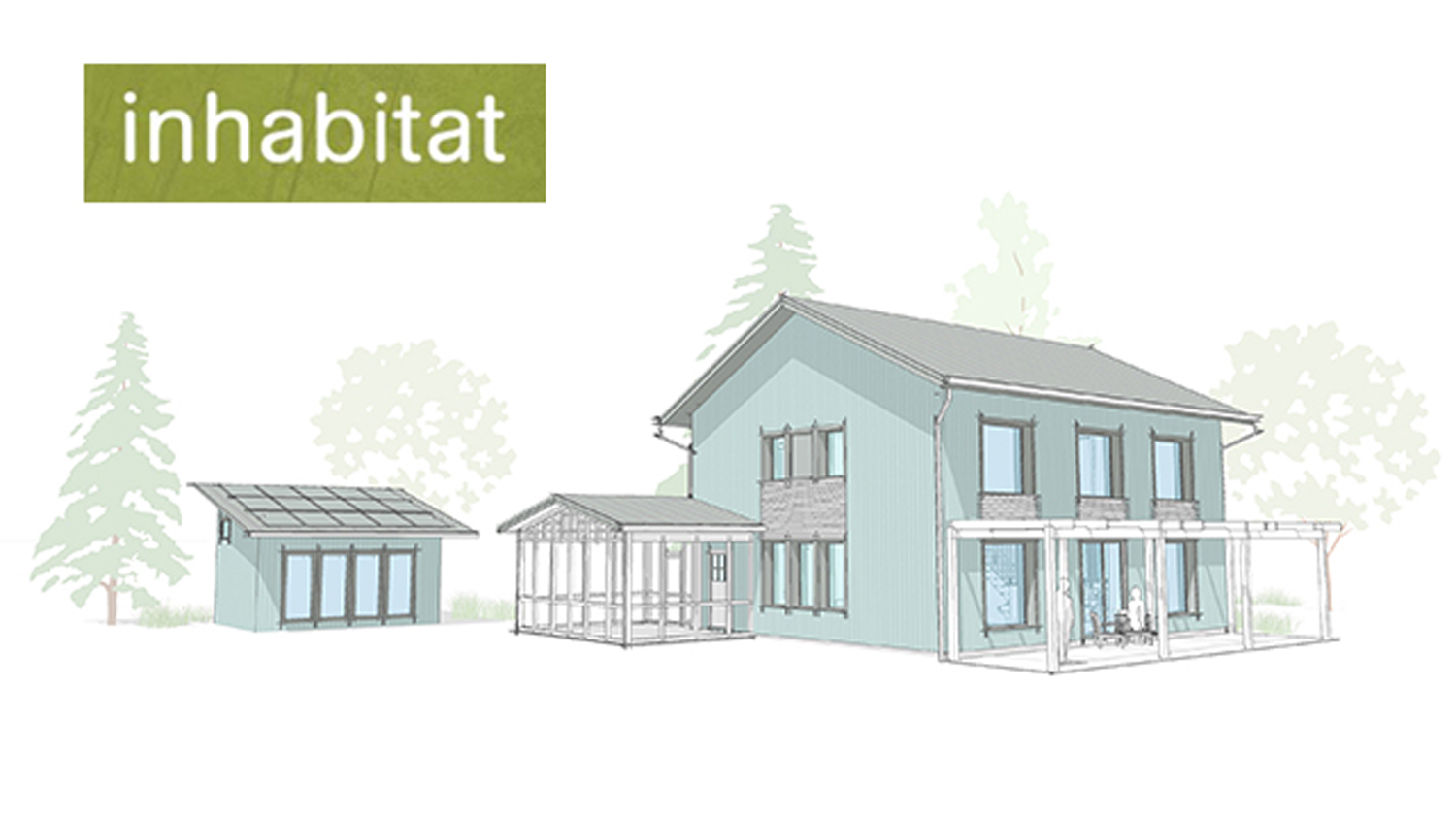

The Ecocor-RPA partnership launched today with the unveiling of eleven prefabricated passive house model home designs that range from a 323-square-foot one-bedroom cabin to a 2,685-square-foot three to four-bedroom house. Passive House, a term which refers to a set of rigorous standards for ultra low-energy homes that provide high levels of comfort, has been used by manufacturers in numerous European countries but has yet to be popularly adopted in North America. Ecocor is the first company in North America to begin manufacturing prefabricated Passive Houses, and is also the only company in the continent to have Passive House Institute (PHI)-certified opaque prefabricated building components. Ecocor’s foundation and wall designs can reduce energy consumption for heating and cooling buildings by an incredible 80 to 90 percent.

“Richard Pedranti and I are looking to establish industry best practices for delivering beautiful certified Passive Homes in the United States,” said Chris Corson, Founder and Technical Director at Ecocor. “RPA’s designs combined with Ecocor’s state-of-the-art equipment and proven processes allows us to deliver the highest quality energy efficient homes available domestically.” The homes will be built in a controlled environment at the Ecocor factory before they are delivered and assembled on sites evaluated and optimized for Passive House construction. The prefabrication and assembly process minimizes construction time and site disturbance.

In addition to the eleven house models, clients will have the chance to work with RPA to design a unique and custom Passive House build. Any changes in design will be plugged directly into Building Information Modeling (BIM) software, which reduces costs and shortens the pre-construction phase. That data is directly integrated into the manufacturing software used in the machines that build the home’s prefabricated components. Ecocor and RPA aim for PHI and Passive House Institute US (PHIUS) certification for all the Passive Houses produced.

In addition to the eleven house models, clients will have the chance to work with RPA to design a unique and custom Passive House build. Any changes in design will be plugged directly into Building Information Modeling (BIM) software, which reduces costs and shortens the pre-construction phase. That data is directly integrated into the manufacturing software used in the machines that build the home’s prefabricated components. Ecocor and RPA aim for PHI and Passive House Institute US (PHIUS) certification for all the Passive Houses produced.

See this article on http://inhabitat.com/north-americas-first-fully-prefabricated-passive-houses-could-revolutionize-the-housing-market/.